01

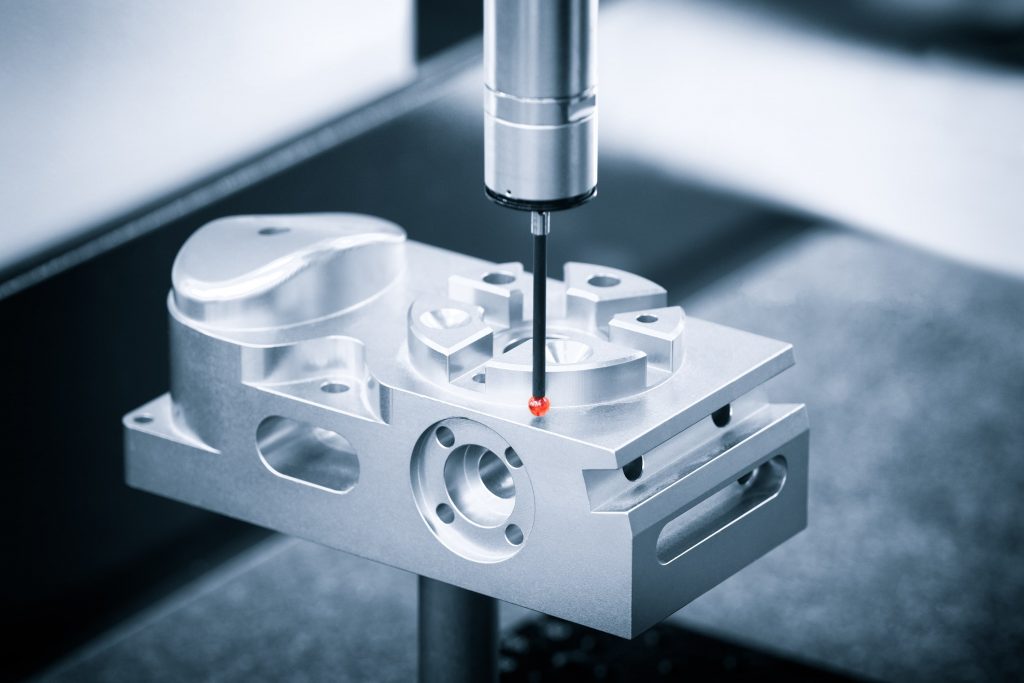

CNC Machining Center

Quickly access your CNC Processes (3-5 axis), CNC Laser cutting and Bending, Wire Erosion, Plunge Erosion, High precision machined metals, polymer and composite parts.

02

CNC Turning Service

We are offering the fastest, high presicion CNC Turning service solutions to you

Follow Your Production Live

We strive for excellence in everything we do.

You can follow the stage of production on our web platform, whether from your computer or your phone. See the time left to delivery.

Cras ultricies ligula sed magna dictum.

We meet all your production needs in our large production center

With our expert engineers and technicians, we work to ensure that your productions reach you at the fastest time and most competitive prices. We offer a wide range of production services from mass production to individual productions. Our center in Istanbul, helps you with processing and measuring services of many materials.

You can contact us now, get the production offer of the part you want and start producing it right away.

Cras ultricies ligula sed magna dictum.

CNC Turning Services Overview

CNC abbreviation stands for ‘Computer Numeric Control’. It is a type of lathe machine that allows many jobs that require manpower to be made easier and to make mass production. Its purpose is to control machine tools via computer and numerical commands. CNC lathes are used with NC programs. Thus, the workpieces are completed in a short time with the specified speed, progress and measure. CNC usage is common in agriculture, automotive and machinery industry.

CNC technology is used for error-free production in manufacturing. Offset and technical information can be permanently stored in the memory of CNC machines with the help of computerized control unit. It is possible to intervene in the program at every stage of production and make the desired changes. CNC technology is also used in the defense sector, aviation, spare parts production and furniture. We come across CNC benches in many areas including welding, machining, mockup and model mold production and theme parks. Our company offers services in CNC production.

Cras ultricies ligula sed magna dictum.

What is CNC?

What is CNC? If we answer this question in a little more detail, we can add the following:

CNC cutting is also called ‘Router Cutting’. It allows shapes to be cut, scraped and drilled in two or three dimensions. It is widely used in many materials such as PVC, wood, marble, plastic, acrylic, aluminum and copper.

This modern method is often preferred for cutting and shaping hard materials. The prepared technical drawing is processed on the materials using CAM and CAD software. This procedure is called CNC cutting.

CNC machine consists of a table and cutting head. In addition to the standard CNC system; There are also types such as CNC laser, plasma and oxygen cutting.

Cras ultricies ligula sed magna dictum.

CNC Metal Cutting

CNC metal cutting is an application that can be easily performed on metals with a high degree of hardness.

Besides cutting metals, it also allows to create different formula structures.

It gives the desired shape to the metals, moreover, it saves time by doing this quickly.

There are different methods that can be used for metal cutting:

⚫ CNC Oxygen

If metals are to be processed with this technique, the materials must react with a flammable gas. This produces a high degree of heat. The heated section is cut with an oxygen gas set. After this process, the metal is burned by the oxygen. The metal then, blows the oxide out from behind the material.

In order to carry out the metal cutting process successfully, the melting in the oxides must be less than the metal. On the other hand, it is important that the oxides have a fluid structure.

⚫ CNC Plasma Cutting

It is one of the most preferred methods in metals. It’s biggest advantage is that it can be applied to all conductive metals.

⚫ CNC Laser Cutting

The processing of metals with laser optics is called CNC laser cutting. Laser cutting have widespread usage area in mass production processes

As TalosHub, we do all your CNC Cutting and Machining operations with our Professional team. You can reach us 24/7 on our contact page.

Cras ultricies ligula sed magna dictum.

Materials for CNC machining

Take advantage of our material network with the widest range on the market. There is no material that we can not provide in a short period of time for your turned parts. If it does, we will almost always find a suitable alternative.

Plastic procesed parts

Choosing the plastics:

- PA6 GF15

- PA6 GF30

- PA66 GF30

- PEEK GF30

- POM GF30

- PP GF30

- PPS GF40

- Etc.

- ABS

- PE UHMW

- PMMA (Acrylic Glass)

- PVC

- PVC-U(Tough PVC)

- PP

- PS

- PTFE (Teflon)

- etc.

Cras ultricies ligula sed magna dictum.

Surface treated CNC turned parts

By commissioning us for the complete processing, including surface finishing, you no longer need to waste time searching for another suitable company or additional logistics. In addition, we remain your only contract partner throughout the entire production process and take responsibility for the impeccable quality of the surface treatments.

Choosing Available Surface Processe

- Hardening

- Damping and Tempering

- Gas Nitriding

- Plasma Nitriding

- Etc

- Eloxal

- Tough Eloxal

- Black Coating

- Neutralization

- Nickel Coating

- Galvanization ( Galvanic Coating)

- Etc.

- Laser Processing

- Polishing

- Griding

- Sandblasting

- Glass bead blasting

- Etc

CNC Turning – From Prototype to Mass Production

When it comes to CNC prototyping, every day is often important. Online Production has become synonymous with speed. Thanks to our extensive network of manufacturers, we always have free capacities and short lead times of 9-12 working days.

TALOSHUB We offer a one-stop solution to all your production needs. Our expert engineers and technicians are working to complete your productions in the most accurate way.

Online Production and large-scale production are also advantageous. With the smart selection of highly specialized manufacturers, it is possible to produce large quantities cost-effectively. Let us check for free whether we can lower your current purchase prices.

Frame agreements offer companies long-term price stability and thus planning security. Frame agreements for CNC machined parts can be individually designed and tailored to your needs with TALOSHUB.